|

Winterizing

Your Sprinklers

|

| Tips

From Rain Bird to Help Keep Your Sprinklers Safe Until Next

Spring |

|

CAUTION!

WEAR PROPER EYE PROTECTION!

Extreme care must be taken when blowing out the system to avoid

excessive pressure which can damage valves or sprinkler pipe or

cause physical injury due to flying debris. Do not stand over

any irrigation components (pipes, sprinklers, and valves) during

air blow out. Air pressure must not exceed 50 pounds per square

inch (psi). |

| Without

proper preparation your sprinkler system can be damaged by freezing

temperatures. Here are some tips from Rain Bird on how to prepare

your irrigation system if you live in a region where it freezes. |

1.

Insulate your assets.

Shut

off the water supply to the irrigation system. The main shut off

valve for your irrigation system needs to be protected against

freezing. To prevent it from freezing make sure it is wrapped

with insulation (foam insulation tape and a plastic bag), or somehow

protected from freezing. If you do not have a main shut off valve,

consider it a preventative investment. Any above ground piping

needs to be insulated. Self-sticking foam-insulating tape or foam

insulating tubes commonly found at home supply stores, are fine. |

2.

Stay in control.

If

you have an automatic system then you will need to "shut

down" the controller (timer). Most controllers have a “rain-mode"

which simply shuts off the signals to the valves. The controller

continues to keep time, the programming information (start times,

valve run times, etc,) isn't lost, and the clock continues to

run. The only change is that the valves will not activate. If

your controller is responsible for activating a pump, as a precaution,

remove the wires that are connected to the MV and common. This

will prevent the possibility of the pump from being activated

which could cause overheat damage.

An

alternative to using the rain mode is simply to shut off the power

to the controller. If you do, you'll need to reprogram the time

and potentially all your other settings as well, in the spring. |

3.

Drain the pipes.

Now

you need to remove the water from the pipes and sprinklers so

that it won't freeze and break the pipe. There are several ways

to drain your pipes: the manual drain valve, the automatic drain

valve or the compressed air blow-out methods. However, since there

could be potential safety risks we recommend contacting your local

irrigation specialist. |

4.

Protect valves and backflow preventers.

Insulate

backflow preventers and valves if they are above ground. You can

also use insulation tape for this. Do not block the air vents

and drain outlets on backflow preventers.

Please

review the Rain Bird Homeowner's Guide to Winterization for detailed

instructions on how to prepare your irrigation system for the

Winter months.

Rain Bird Homeowner's Guide to Winterization |

| http://www.rainbird.com/pdf/diy/WinterizationGuide.pdf |

|

Winterizing

Your Irrigation System

Courtesy of Hunter |

|

|

| Every year, before the first freeze, the ritual of irrigation

"blow out" becomes the priority for all irrigation

systems that are in parts the country where the frost level

extends below the depth of the installed piping. |

Even

if you have drained some water out of the system, the remaining

water can freeze, expand and crack the PVC piping (rigid, white

pipe), usually from fitting to fitting. Polyethylene pipe (flexible,

black pipe) is used in many freezing climates. Although polyethylene

pipe is more flexible and can expand under pressure, water left

inside could freeze and rupture the pipe walls. Freezing water

in the backflow assembly will damage the internal components

and could possibly crack the brass body.

To

minimize the risk of freeze damage to your irrigation system,

you’ll need to "winterize" your irrigation system

Irrigation

systems in areas where "winterization" is mandatory

are installed using one of three types of water removal in mind:

manual drain, auto drain, or blowout. If you don’t know

your system type, it would be best to use the blowout method. |

Manual

Drain Method

Use when manual valves are located at the end and low points

of the irrigation piping. To drain these systems, simply shut

off the irrigation water supply (shut off will be located in

the basement and will be either a gate/globe valve, ball valve

or stop and waste valve - see drawings below) and open all the

manual drain valves. Once the water has drained out of the mainline,

open the boiler drain valve or the drain cap on the stop and

waste valve (whichever is used in your area) and drain all the

remaining water that is between the irrigation water shut off

valve and the backflow device. Open the test cocks on the backflow

device. If your sprinklers have check valves you’ll need

to pull up on the sprinklers to allow the water to drain out

the bottom of the sprinkler body. Depending on the location

of the drain valves, there could be some water left in the backflow,

the piping and the sprinklers. When all the water has drained

out, close all the manual drain valves. |

Automatic

Drain Method

Use when automatic drain valves are located at the end and low

points of the irrigation piping. These will automatically open

and drain water if the pressure in the piping is less than 10

PSI. To activate these, you shut off the irrigation water supply

(shut off will be located in the basement and will be either

a gate/globe valve, ball valve or stop and waste valve - see

drawings below) and activate a station to relieve the system

pressure. Once the water has drained out of the mainline, open

the boiler drain valve or the drain cap on the stop and waste

valve (whichever is used in your area) and drain the remaining

water that is between the irrigation water shut off valve and

the backflow device. Open the test cocks on the backflow device.

If your sprinklers have check valves you’ll need to pull

up on the sprinklers to allow the water to drain out the bottom

of the sprinkler body. Depending on the location of the drain

valves, there could be some water left in the backflow, the

piping and in the sprinklers.

In

some areas you might have a combination of the manual drain

system on the mainline (the pipe between the irrigation water

shut off valve and the valves) and auto drain system on the

lateral lines (the pipe between the valves and the sprinklers). |

"Blow

Out" Method

It is recommended that a qualified licensed contractor perform

this type of "Winterization" method, The blow out

method utilizes an air compressor with a Cubic Foot per Minute

(CFM) rating of 80-100 for any mainline of 2" or less.

These types of compressors can be rented at your local equipment

rental yard. The compressor is attached to the mainline via

a quick coupler, hose bib or other type connection, which is

located after the backflow device. Compressed air should not

be blown through any backflow device. To start the "blow

out", shut off the irrigation water supply and, with the

compressor valve

in

the closed position, attach the air compressor hose to the fitting.

Activate the station on the controller that is the zone or sprinklers

highest in elevation and the furthest from the compressor. Close

the backflow isolation valves. Then slowly open the valve on

the compressor; this should gradually introduce air into the

irrigation system. The air pressure should be constant at 50

PSI. If the sprinkler heads do not pop up and seal, increase

the air pressure until the heads do pop up and seal. The air

pressure should NEVER exceed 80 PSI.

Each

station/zone should be activated starting from the furthest

station/zone from the compressor slowly working your way to

the closest station/zone to the compressor. Each station/zone

should be activated until no water can be seen exiting the heads,

this should take approximately two minutes or more per station/zone.

It is better to use two or three short cycles per station/zone

than to have one long cycle. Once the station/zone is dry, you

should not continue to blow air through the pipe. Compressed

air moving through dry pipes can cause friction, which will

create heat and the heat could cause damage. |

Additional

Steps

Once the water has been removed from the irrigation system,

disconnect the air compressor and release any air pressure that

may be present. If your backflow device, the most common backflow

installed is called a Pressure Vacuum Breaker, has ball valves,

open and close the isolation valves on the backflow device numerous

times to ensure that any trapped water has escaped from the

upper areas. Leave the isolation valves open at a 45° angle

(approximately 1/2 open) and open the test cocks |

|

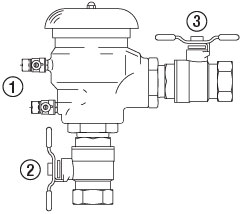

| Pressure

Vacuum Breaker |

Pressure

Vacuum Breaker

- PVB

Test Cocks

- Isolation

Ball Valve Inlet

- Isolation

Ball Valve Outlet

|

|

Interior

Point of Connection Freezing Climates

- Boiler

Valve

- Irrigation

Shut Off Valve

- Main

Water Shut Off Valve

- Water

Meter

|

|

| Types

of Valves |

|

|

|

|

Gate

Valve |

Ball

Valve |

Stop

& Waste Valve |

Boiler

Valve |

|

| Preparing

a hydraulic control system? Shut off the water supply

to the signal control tube(s) and drain the field tubing. |

| Outdoor

mounted controllers? Leave the power on and the dial

/ switch in the "Off" position. The heat from the

transformer will keep the enclosure warm enough to keep condensation

from forming inside the controller enclosure. The dial in the

"OFF" will keep the controller from activating the

solenoids in the field. |

Indoor

mounted controllers? You may either leave the power

on and the dial/switch in the "Off" position OR you

may remove the battery backup and unplug the transformer. |

| Rain

Sensors? There is not much to do to prepare the rain

sensor for the winter months. If your sensor is the type with

a cup or bowl that catches water, you might want to remove the

water and place a plastic bag over the sensor. This will keep

any water from accumulating and freezing in the cup or bowl

area. If your sensor is the type that uses wafers or discs,

you might want to remove the wafers and store them in the garage

for the winter months. This will keep damp wafers from freezing. |

The

Do NOTS of "BLOW~OUT" Winterization

Do not allow the air pressure to exceed 80 PSI for systems with

PVC piping and 50 PSI for systems with polyethylene piping.

Do not stand over component parts while the system is pressurized

with air.

Do not leave the air compressor unattended.

Do not blow the system out through a backflow or pump. First

blow out the system, then drain the backflow or pump.

Do not leave the manual drain valves open after the blow out. |